How to Maintain and Refinish Hardwood Floors for Long-Term Durability

How to Maintain and Refinish Hardwood Floors for Long-Term Durability

Homeowners researching hardwood maintenance are typically seeking clear steps that preserve the appearance and prevent long-term surface damage. This overview explains how daily care, periodic cleaning, climate control, and refinishing cycles affect service life. It also describes when sanding is necessary and how to evaluate structural wear. By the end, homeowners can establish maintenance routines, identify refinishing indicators, and understand how durability expectations apply to

hardwood flooring in Carlsbad, CA, or any comparable environment.

What routine maintenance keeps hardwood floors stable over time?

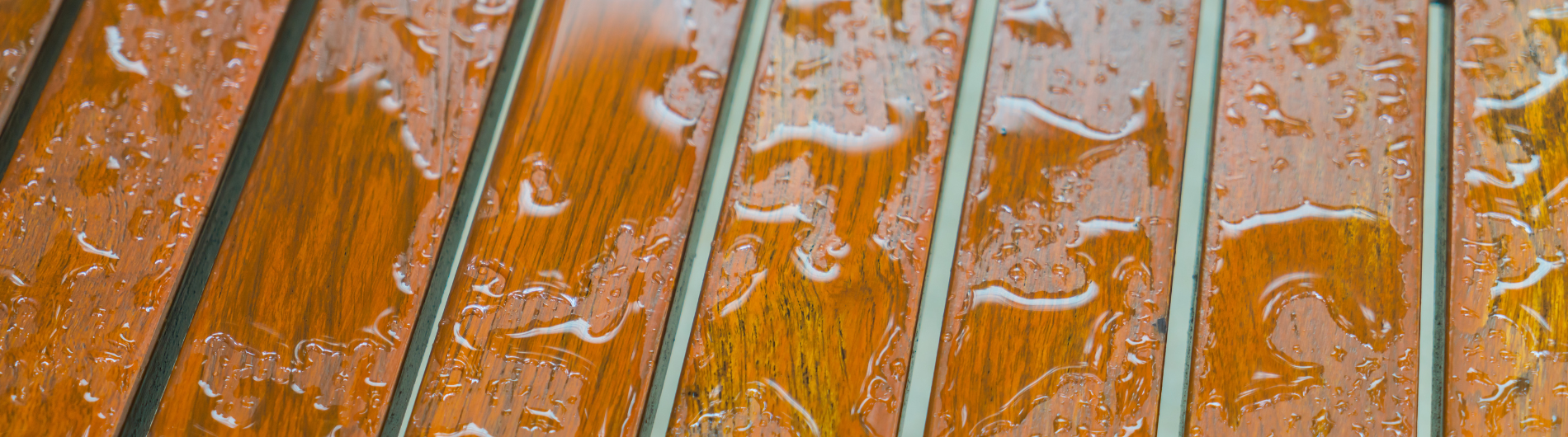

Hardwood flooring requires controlled moisture, routine debris removal, and prevention of surface abrasion. Floors should be swept or vacuumed regularly to prevent the accumulation of grit, which can scratch protective coatings. Mats near entry points reduce tracked-in particles that accelerate finish wear. Homeowners should avoid prolonged exposure to standing water because wood fibers absorb moisture and may expand or distort.

Routine cleaning should use products formulated for wood finishes rather than heavy detergents. Strong alkaline cleaners can dull surface coatings and accelerate refinishing cycles. The goal is to maintain the protective layer, so refinishing is only required when abrasion becomes visible.

How does moisture control affect hardwood longevity inside a home?

Moisture is one of the primary factors affecting hardwood performance because wood expands and contracts with humidity changes. Indoor humidity between approximately 30% and 50% generally limits dimensional movement. Excess humidity can introduce cupping, where board edges rise due to moisture absorption. Low humidity can produce gaps between boards as fibers contract and lose moisture.

Homes in coastal regions such as Carlsbad and Oceanside may track humidity seasonally, making mechanical ventilation and controlled airflow useful. Climate consistency reduces stress on wood connections and lowers the risk of finish cracking. When homeowners maintain stable conditions, refinishing intervals remain longer because surface film breaks down less rapidly.

Which surface threats shorten the service life of hardwood floors?

Surface wear originates from abrasion, chemical exposure, foot traffic, and debris. High-use areas create micro-scratches that slowly erode polyurethane finishes. Repetitive sliding of furniture legs can cut through protective layers and expose bare wood. Pets with sharp claws increase scratch density, which can lead to early sanding needs.

Liquid spills pose a risk because moisture intrusion through damaged finish can stain or discolor boards. Oil-based substances can penetrate hardwood fibers and become difficult to remove without sanding. When these conditions persist, surface coating loses uniformity, and boards require refinishing earlier than expected.

How can homeowners reduce scratch formation and finish abrasion?

Reducing abrasion begins with protective barriers between hard materials and the wood surface. Felt pads on furniture legs minimize direct friction when items shift. Area rugs in high-traffic zones disperse foot impact and protect finishes from concentrated wear. Vacuum attachments should use soft bristles rather than beater bars, which can score coatings.

Footwear management also matters. Hard-soled shoes and high heels create point loads that damage coatings. Removing outdoor shoes minimizes grit movement across surfaces. Over time, reduced abrasion translates into longer intervals between refinishing cycles and a more consistent appearance.

What cleaning practices prevent finish degradation?

Cleaning should support the existing finish rather than force surface removal. Damp mopping is acceptable when equipment is well wrung and appropriate cleansers are used. Excessive water should be avoided because it can seep into joints and compromise adhesives or subfloor systems. Steam mops introduce heat and vapor pressure that may damage coatings and are not recommended for hardwood.

Manufacturers commonly recommend pH-balanced cleaners that leave minimal residue. Residue buildup can attract soil and dull surface sheen. Homeowners should avoid wax products unless the flooring was originally finished with wax, because applying wax over polyurethane can limit refinishing options by creating contamination layers.

How do homeowners know when buffing or screen-and-recoat services are appropriate?

A screen-and-recoat process removes the top layer of finish without sanding down to bare wood. This method is suitable when scratches exist only in the surface coating and have not penetrated the wood. If sheen is irregular, or if foot patterns appear dull but no exposed wood is visible, a recoat can restore uniform protection.

Buffing is effective when the goal is surface preparation rather than material removal. It improves adhesion for a new coat and slows further wear. Screening and recoating are generally required more frequently than full sanding and can extend the time before deeper refinishing.

When do hardwood floors require full sanding and refinishing?

Full sanding is necessary when finish layers are fully worn, and wood fibers are exposed. Deep scratches and dents that exceed coating thickness cannot be corrected with surface sealing. Discoloration from water, stains, or UV exposure may require sanding if pigment has penetrated below the coating.

Refinishing cycles vary by species, finish type, traffic, and maintenance. Floors with multiple surface tears, cupping that has stabilized after humidity correction, or severe unevenness often need complete resurfacing. Sanding restores a uniform wood surface before new coats are applied, which prevents localized weak points.

How does wood species influence durability and refinishing outcomes?

Wood species vary in hardness, cellular density, and grain direction. Harder species resist indentation and are slower to show compression wear. Oak, maple, and hickory are frequently selected in high-traffic spaces because their cellular composition disperses force. Softer woods like pine compress more easily and may require refinishing sooner.

Grain structure also influences visual results. Species with strong grain patterns, such as red oak, mask scratches more effectively than smooth-grained woods like maple. When sanding, denser species require more abrasive control to prevent uneven removal. Understanding species traits gives homeowners realistic expectations about long-term maintenance cycles.

How do finish types affect maintenance frequency and refinishing needs?

Polyurethane finishes create a protective film that resists abrasion and moisture better than older varnish systems. Oil-based polyurethane forms a thicker coat and may amber over time. Water-based polyurethane maintains a clearer appearance and typically introduces less odor during application. Both finishes require periodic screening to maintain surface thickness.

Penetrating oil finishes behave differently because they reside within wood fibers rather than forming a surface film. Oil finishes require more frequent re-oiling to maintain saturation and protection. Although oils generate a natural appearance, they offer less barrier protection against moisture and scratches, which may lead to shorter refinishing intervals.

What signs indicate early deterioration in hardwood flooring?

A floor showing widespread dulling, visible surface scratches, or uneven sheen is experiencing coating deterioration. If edges begin to cup or boards crown, a moisture imbalance is present. Creaking, shifting, or vertical movement may indicate fastener issues or subfloor changes.

Stains that persist after surface cleaning suggest finish penetration. When discoloration accompanies texture differences, sanding may be the only corrective measure. Monitoring these conditions allows homeowners to intervene before structural effects occur.

Can engineered hardwood be refinished like solid hardwood?

Engineered flooring contains a hardwood veneer attached to a supportive core. Refinishing depends on veneer thickness. Thick wear layers tolerate several sanding cycles, while thinner layers may only support a light abrasion. When veneers are insufficient for sanding, only recoating is feasible.

Engineered flooring remains stable in humidity fluctuations because its core layers run cross-directionally. This reduces cupping and gapping but does not eliminate surface wear. Homeowners should verify wear-layer depth before planning refinishing work to avoid damaging the veneer.

What preparation is required before scheduling a refinishing project?

Preparation begins with surface evaluation. Homeowners should identify deep gouges, water damage, or subfloor issues before sanding. Loose boards should be secured to prevent movement during abrasive contact.

Furniture removal, access planning, and ventilation considerations should be addressed early. Sanding produces dust, and modern collection systems vary. Evaluating whether a screen-and-recoat suffices can prevent unnecessary sanding and preserve total wood thickness.

How does proximity to coastal climates affect hardwood maintenance expectations?

Coastal areas show higher ambient humidity and material exposure to salt-air particulates. Hardwood flooring in Oceanside, CA, may require more frequent humidity control. Entry mats are useful for collecting sand, which can abrade coatings.

Although wood remains structurally reliable in these climates, maintenance intervals may shorten if humidity fluctuates widely. Consistent indoor conditioning stabilizes wood fibers and reduces the likelihood of cupping.

Frequently Asked Questions

Can hardwood floors be steam-cleaned?

No. Steam introduces moisture and heat that can damage wood and compromise finish films.

How often should hardwood floors be refinished?

Timing depends on wear, but refinishing is generally required only when surface coatings are visibly worn or when wood is exposed.

Do area rugs help preserve hardwood longevity?

Yes. Rugs reduce abrasion and absorb foot traffic, slowing coating deterioration.

Key Takeaway

- Controlling moisture and abrasion is the most reliable way to extend hardwood lifespan.

- Routine screening delays the need for full sanding and preserves structural thickness.

- Refinishing is only required when coatings fail or wood fibers are visibly compromised.

A Final Thought

Hardwood floors remain durable when maintenance supports their natural movement and protects finish layers. Establishing consistent habits allows homeowners to plan refinishing based on observable conditions rather than guesswork. With stable cleaning, climate control, and abrasion prevention, long-term performance becomes predictable.